Finnish industry needs to reduce emissions further

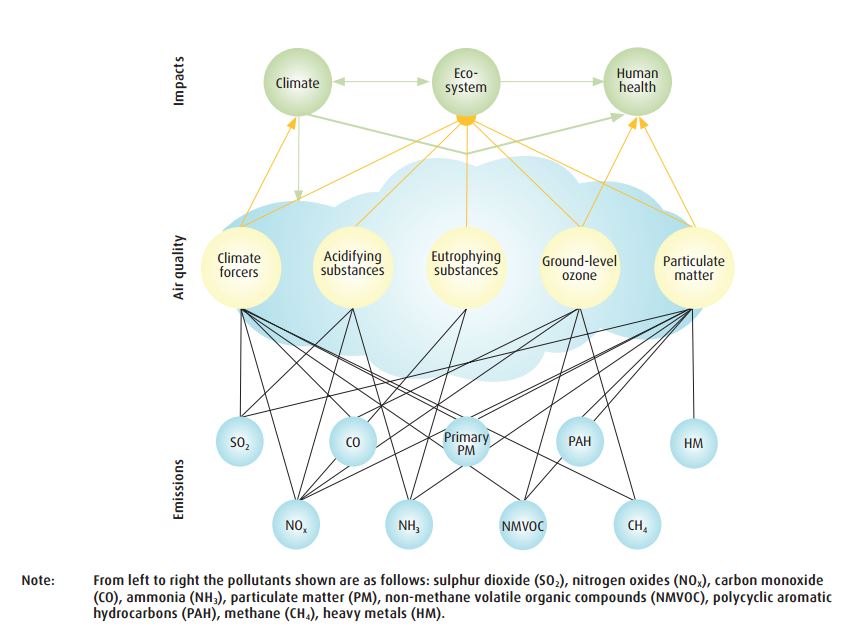

Air pollution from industry and increasing road transport creates a complex system in which different impurities react with each other in the atmosphere, affecting our health, the environment and the climate. Environmental protection has come a long way in modern industrialised societies, and more effective methods have been developed to control emissions. The quality of air and water has improved significantly in many areas compared to the situation just a few decades ago. However, there is still much room for improvement.

European Union directives have made legislation in different countries more in line with each other, and emissions norms are now set primarily on the EU level. The task of local authorities is to implement the supervision of industrial emissions in their region by means of permitting. Industrial emissions norms are regulated today by the Industrial Emissions Directive, for example.

The National Emissions Ceiling Directive (NECD) sets limits on the national level for four of the main types of emissions:

• Nitrogen oxides (NOx)

• Sulphur oxides (SOx)

• Non-methane volatile organic compounds (NMVOC)

• Ammonia (NH3)

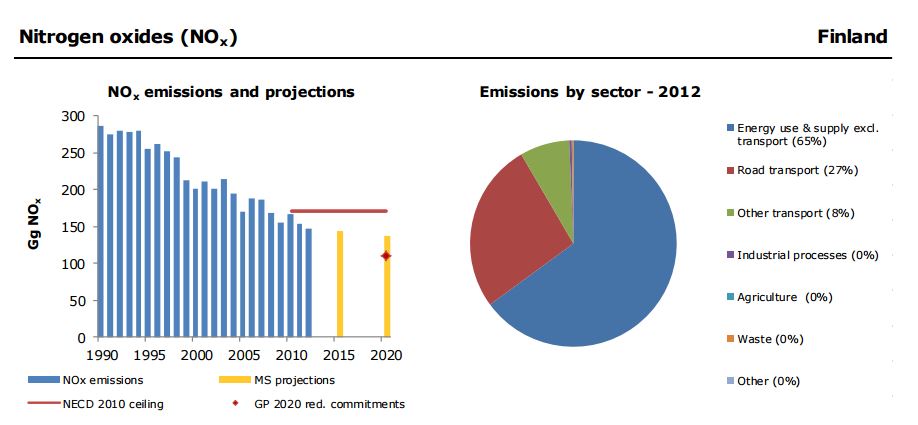

Source: European Environment Agency (EEA), Air pollution fact sheet 2014, Finland

According to EEA reports, the energy sector and industry in both Finland and Sweden account for the highest or second highest share of all emissions on the national level in the following categories:

NOx (Finland 65%, Sweden 41%)

SO2 (Finland 94%, Sweden 52%)

NMVOC (Finland 52%, Sweden 24%)

Fine particles, PM2.5 (Finland 74%, Sweden 52%)

Carbon monoxide, CO (Finland 61%, Sweden 57%)

The energy sector and industry have worked for many years already to reduce especially their SOx and NOx emissions, but there is still room for improvement in terms of both performance and requirement levels. The Industrial Emissions Directive requires Finnish industry in particular to reduce its NOx emissions in the near future.

Source: European Environment Agency (EEA), Air pollution fact sheet 2014, Finland

New requirements for energy producers

Emissions regulation technology is selected for new power plants already in the planning phase. For example, well established cleaning processes for SOx, fine particle and NOx emissions already exist and for the most part are effective. In the future, however, emissions regulations may become stricter or the level of emissions may change by favouring different fuels. It is therefore necessary to invest in new processes, cleaning equipment and storage containers.

Chemical solutions may be unfamiliar to many energy producers, so expert suppliers with comprehensive networks can be of great assistance. At the most basic level, the solution could involve finding the optimal size of storage container. In other cases, the supplier may have the only applicable solution to a specific problem.

Operating costs can be optimised through efficient production and delivery processes. Close cooperation with the supplier also creates the basis for an open discussion about maximum permitted levels and the solutions for staying within these levels. By investing in the environment, the producer is investing not only in people’s health and clean nature, but also in their own future.

Practical chemical solutions for reducing industrial emissions

Algol Chemicals is currently developing a centre of expertise for environmental chemicals at the Kvarntorp plant in Kumla. Kvarntorp has supplied ammonia for agricultural and industrial use for over 20 years. “With the help of our own products and those that we represent, as well as with our own expertise, Algol Chemicals is strongly developing its operations as a major supplier of environmental chemicals for the needs of the energy sector and many other industrial sectors. We offer energy producers the opportunity to source their environmental chemicals from one and the same supplier, everything from small canisters of special chemicals to an entire tanker of reagents for controlling NOx emissions. At the same time we offer practical assistance regarding the handling of chemicals and solving problems,” says Harri Latonen, Development Manager at Algol Chemicals.

A wide range of chemical solutions already exist for reducing emissions. “Anhydrous ammonia is used, for example, as a refrigerant, a fertiliser and a raw material for other chemicals. Dissolving it in pure water creates an ammonia solution that is the most common reagent in SNCR and SCR processes for reducing NOx emissions. The ammonia molecule reacts with the nitrogen oxides in the exhaust gas, creating molecular nitrogen and water,” Latonen explains.

“Basic chemicals, such as sodium hydroxide (caustic soda) and water, are also used for treating exhaust gases. The water used in the cleaning process has to be purified before it is released from the plant. Metals are removed from the water using precipitation chemicals based on ferric chloride and/or polyaluminum chloride. In some cases, heavy metals like mercury, cadmium, copper, nickel, lead, thallium and silver can cause problems. These heavy metals can be contained within complexing agents, in which case the precipitation will not comply with official requirements. By adding the special chemical ACTMT® to the process, the heavy metal complexes can be broken up, allowing the metals to be removed by precipitation. Naturally, we can offer technical support for cleaning processes to help find the most suitable method,” Latonen adds.