We achieved most of our sustainability targets in 2024

At the beginning of 2022, we published our short-term sustainability targets for 2022-2024 in accordance with our strategy. These targets are based on a survey conducted within the company that clarified the key issues of our sustainability work in terms of our customers and other stakeholders.

In 2024, we achieved our supply chain sustainability targets as well as some of our safety targets. We are particularly proud to have been awarded a Gold Medal in the Ecovadis sustainability rating in January 2025 – a result we worked hard for throughout the year 2024.

Our sustainability targets aim to ensure a healthy and well-functioning work community, the sustainable use of energy and resources, and continuous improvement in the quality of our operations. Through concrete actions aimed at achieving our targets, we also participate in the UN Sustainable Development Goals where applicable.

In 2024, our sustainability targets became an even stronger part of our performance management system, and they were increasingly reflected as a clear and concrete part of our day-to-day work.

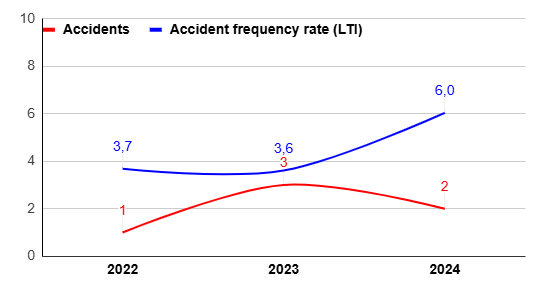

Safety

- Target: 0 accidents and 64 safety walks

- Result: 2 accidents and 66 safety walks

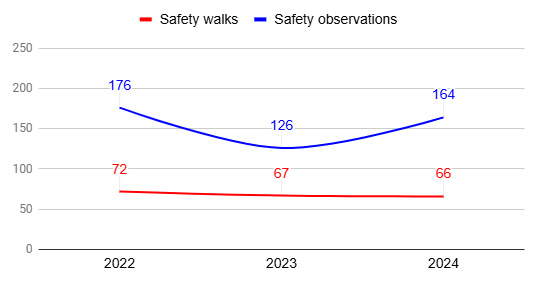

In 2024, employees at our production facilities had personal targets for safety walks and safety observations. Despite the large number of safety walks and safety observations, we did not achieve our target of zero accidents.

Altogether two accidents occurred during the year. One was caused by slipping during a commute, and the other resulted from lifting a heavy sack, which led to a back injury for the employee. These accidents led to a total of 11 days of sick leave. As a corrective measure, we reviewed safe and ergonomic working practices.

Picture 1. Accidents and accident frequency rates 2022-2024.

Picture 2. Development of safety walks and reported safety observations 2022-2024.

Occupational wellbeing

- Target: eNPS 36

- Result: eNPS 21

We monitor the wellbeing of employees by means of regular review and target setting discussions together with occupational wellbeing surveys. Our teams have their own discussion routines that provide supervisors with feedback and allow them to monitor occupational wellbeing factors on a regular basis.

The result of our occupational wellbeing survey conducted in spring 2024 was an eNPS (employee Net Promotor Score) of 21. Altogether 81,4% of employees rated their current work ability as being good or very good. The overall score for occupational wellbeing also decreased from 4,01 in the previous year to 3,97. Although we are satisfied with these results, we continue to focus on clear targets, processes, communications and responsibilities.

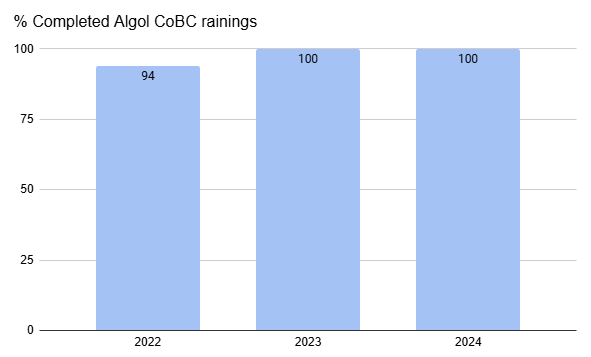

Picture 3. Completed Algol Code of Business conduct training % / personnel 2022-2024.

Supply chain sustainability

- Target: 20 supplier evaluations completed

- Result: 26 supplier evaluations completed

We require all our suppliers and subcontractors to sign our Supplier Code of Business Conduct. In addition, we have guidelines and principles for selecting and evaluating cooperation partners. New suppliers are also carefully evaluated from the perspective of sustainability before being approved. Suppliers who have already been selected as cooperation partners are re-evaluated as needed. In addition, 20 already approved suppliers are selected for evaluations each year. In 2024, we exceeded our target by evaluating 26 existing suppliers. In addition, we evaluated a large number of new suppliers.

Environment

- Target: Sustainable use of resources and reduced emissions

- Result: Amount of chemical waste was reduced

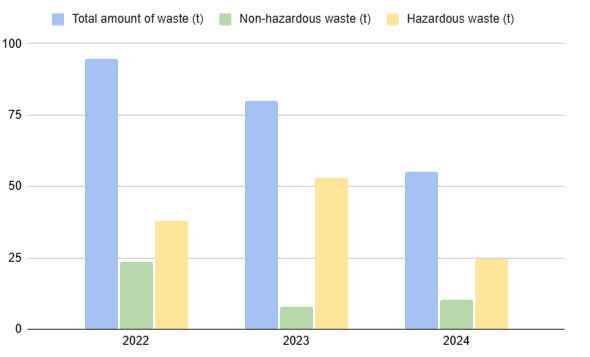

As a distributor and packer of chemicals, the most significant environmental impacts are caused by the use of resources in our own production facilities, the storage of our products, and transportation. In 2024, we continued work to prevent the generation of waste due to product obsolescence. By monitoring product shelf life more effectively, optimising purchase quantities, and working together with supply chain operators, we were again able to reduce the total amount of waste from our products. The amount of hazardous waste was reduced by 54 %, while the total amount of waste was reduced by 31 %.

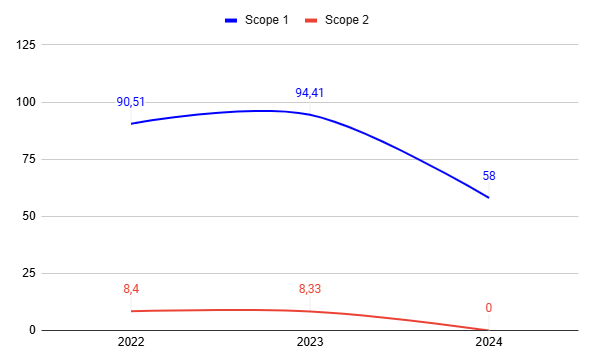

In 2024, we significantly reduced the CO₂ emissions from our own production sites: our net Scope 2 emissions were zero, and we achieved a 39 % reduction in Scope 1 emissions. At our Turku site, we switched to using only renewable fuel oil for heating and forklift operations, which reduced emissions at that site by up to 90%. Our goal was to reduce overall energy consumption and transition entirely to electricity from renewable sources. In 2024, we achieved this goal when our Turku site also made the switch to renewable electricity.

We also collect emissions data from product manufacturers, suppliers and transport companies.

Picture 4. Scope 1 and scope 2 emissions, 2022-2024.

Picture 4. Scope 1 and scope 2 emissions, 2022-2024.

Picture 5. Waste volumes in 2022-2024.